Industry Trend Report|Technology Review and Bottlenecks in Semiconductor Development (Next)

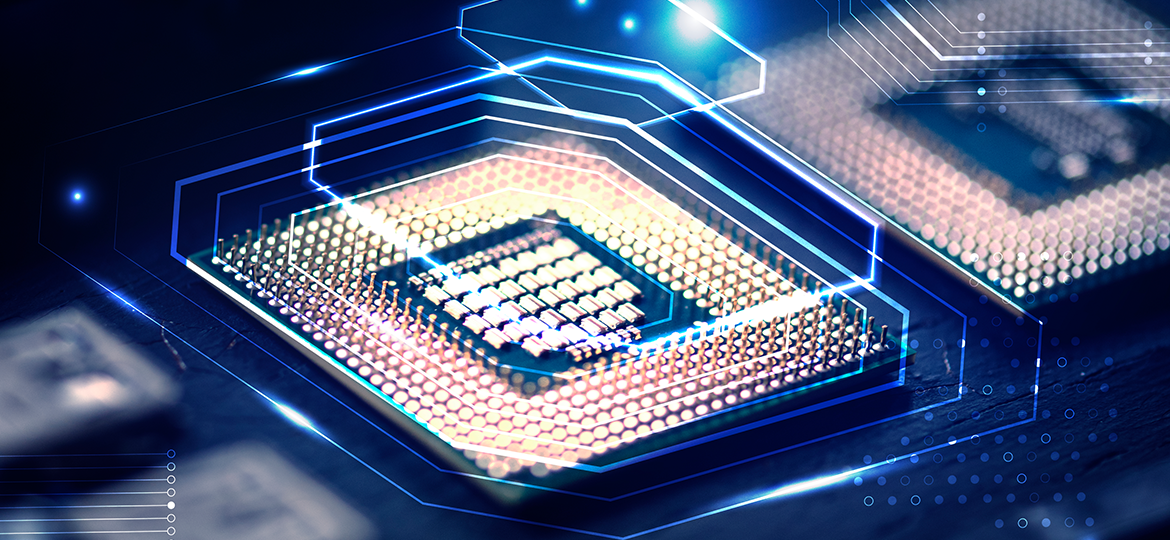

Micrographics is a key process for determining the size of a component, and the exposure machine that creates the circuit pattern on the photoresist is the core equipment. According to the Rayleigh Criterion formula, the minimum linewidth that can be exposed is directly proportional to the wavelength of the light source used in the exposure machine (λ) and inversely proportional to the numerical aperture (NA). Table 1 shows the development of exposure machine technology. Currently, there are only three manufacturers in the world that are capable of developing exposure machines for semiconductor front-end wafer fabrication, namely Nikon, Canon and ASML. At that time, almost all of the exposure machines used by Intel, the leading semiconductor company, were customized by Nikon, while TSMC and Samsung were still small companies in the semiconductor industry, and ASML was just a newly established exposure machine manufacturer. Because the resolution of ArF light source is limited to 65nm, Nikon and Canon chose to develop an exposure machine using a shorter wavelength 157nm light source in order to enable semiconductor front-end processes to move to smaller sizes, but unfortunately encountered major difficulties and failed. ASML not only solved the bottleneck of semiconductor process, but also could be used up to 7nm process with multi-exposure technology. ASML has since become the dominant semiconductor pre-processing exposure machine in terms of market share, and is currently the only company in the world that has the capability to develop and manufacture extreme ultraviolet (EUV) exposure machines. In response to the demand for sub-3nm nodes, ASML and Microelectronics Research Center (MRC) are collaborating on the development of a high-NA EUV exposure machine, which is expected to be launched in 2024, just in time to meet TSMC's and Intel's 2nm mass production schedule. In addition to exposure machines, the Microelectronics Research Center is also developing new photoresist and photomask films for particle contamination prevention. The continuous shrinkage of components increases the difficulty of film coverage and etching, for which equipment vendors have introduced atomic layer deposition (ALD) and atomic layer etching (ALE) equipment, the former of which uses a single layer of atoms to form the film by deposition, and the latter of which uses a single layer of atoms to remove the film by removal. ALD and ALE equipment is only applicable to inorganic materials. As more and more organic materials are introduced into advanced processes, equipment vendors are developing molecular layer deposition (MLD) and molecular layer etching (MLE) equipment, and are also working on the ability to selectively deposit or etch the aforementioned equipment, which reduces the number of micrographic process steps and reduces the amount of equipment to be purchased.